Strategic Value+ Solutions

Enriching Lives Through Manufacturing

GENERATIONAL OPPORTUNITY

Rebuild American Supply Chains.

Win OEM and Government Contracts.

V+ (Strategic Value+ Solutions) is the go-to resource for U.S. SMMs to access reshoring OEMs and federal/state buyers. We help you prove readiness, package evidence, and get into real sourcing workflows—fast.

Strategic Value+ Solutions (V+) equips American manufacturers to compete and win in the new reshoring era. We translate buyer requirements—commercial and Government—into a practical, time-boxed plan you can execute. Our alliance network covers quality, operations, digital twins, robotics, cybersecurity, ESG, accounting and finance, advanced manufacturing, energy, workforce upskilling, government contracts, and opportunity zones, so you get one accountable partner from readiness to ramp and award.

ATTENTION: U.S. Original Equipment Manufacturers

Introducing EDGE-XTM

The Antifragile Transformation Framework for U.S. OEMs.

Smarter. Faster. Resilient. Built for the Next Era of Manufacturing.

Transforming U.S. Manufacturing --

Step by Step

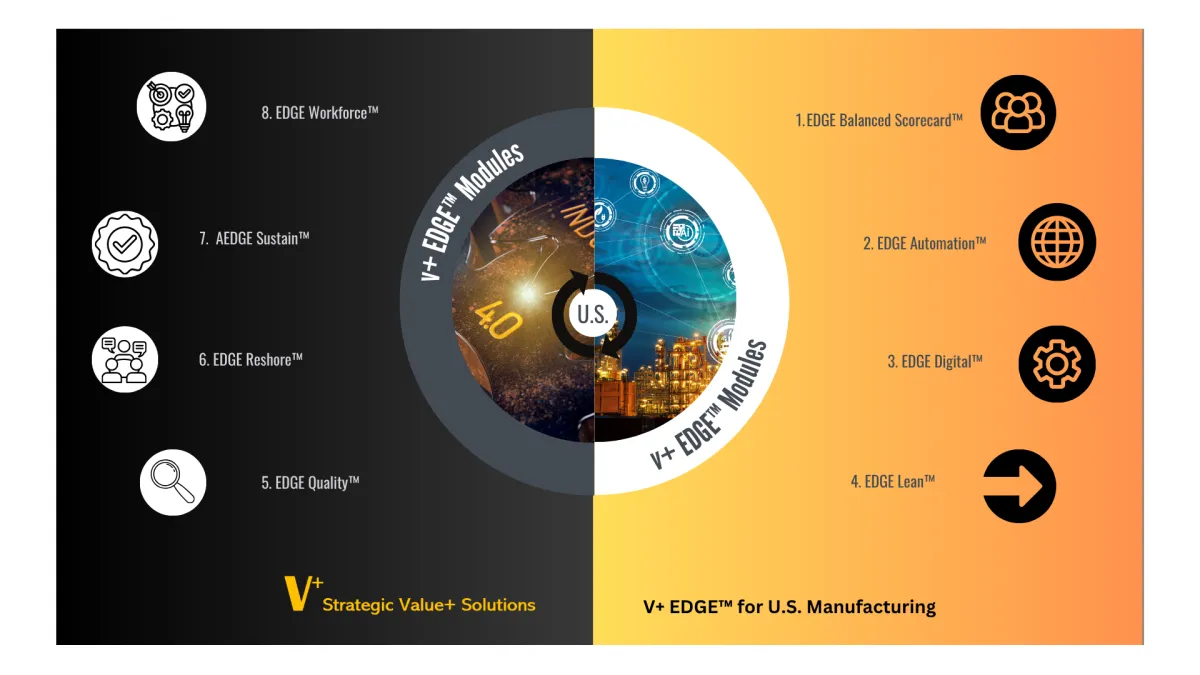

Modular Industry 4.0.5.0 for Manufacturers

We help small- and mid-sized manufacturers drive real, scalable progress. Our modular EDGE™ platform is designed to start where you need it most — then expand with purpose, precision, and measurable results.

Whether you're optimizing operations, reshoring supply chains, or making smarter executive decisions, our

system adapts to your goals and grows with you.

Explore Our Three EDGE™ Platforms Designed to

Deliver Clarity, Speed, and Results.

🛠️ V+ EDGE™

V+ EDGE™ is your entry point to transformation. With flexible modules covering lean, automation, sustainability, quality, and workforce strategy, it’s built to match your priorities. Blend what you need. Scale when you're ready. No ERP overhauls required.

Hands-on implementation with real-time KPIs

Modular design for immediate impact

Ideal for companies with 25–500 employees

🌐 TwinEDGE™

Simulate. Optimize. Reshore with Confidence.

TwinEDGE™ puts the power of digital twin technology in your hands. Model workflows, test scenarios, and redesign supply chains before making costly changes.

Predictive simulations & machine maintenance, and ROI modeling

Smart reshoring and supply chain reengineering

Factory layout, flow, and resource optimization

📈 IntellEDGE™

Decide Smarter. Lead Stronger.

IntellEDGE™ is your strategic layer — bringing executive-grade decision-making tools to your fingertips. From predictive analytics to Agentic AI, it equips leadership teams to act faster and smarter.

Data-driven real-time dashboards, insights and prescriptive decision tools

Scenario modeling for executive strategy

Enhances visibility, agility, and long-term planning

INTRODUCING V+ EDGE™ – THE Transformation FRAMEWORK for U.S. Manufacturers

What Makes V+ EDGE™ Different? Innovative Transformation for Manufacturers with 25 to 500 Employees.

In a world full of buzzwords and bloated systems, V+ EDGE™ delivers practical innovation — modular, fast-start transformation tools designed specifically for small and mid-sized manufacturers (SMMs)

While big-box consulting firms push one-size-fits-all programs, we’ve built an agile, results-first that:

Bridges the Gap Between Lean and Industry 4.0:

V+ EDGE™ combines hands-on lean improvement with smart, accessible digital tools and AI-assisted automation—without requiring a massive IT team or ERP overhaul.

Industry 4.0, Demystified:

From MES-lite dashboards and visual T-Card systems to AI-powered automation pilots, V+ EDGE™ brings next-generation tools to your floor without complexity or cost creep.

Modular by Design. Scalable by Nature:

Each V+ EDGE™ engagement includes real-time KPI dashboards, ROI modeling, and transformation scorecards. You get results you can measure—not just theory.

ATTENTION: Small- & Medium-Sized U.S. Manufacturers

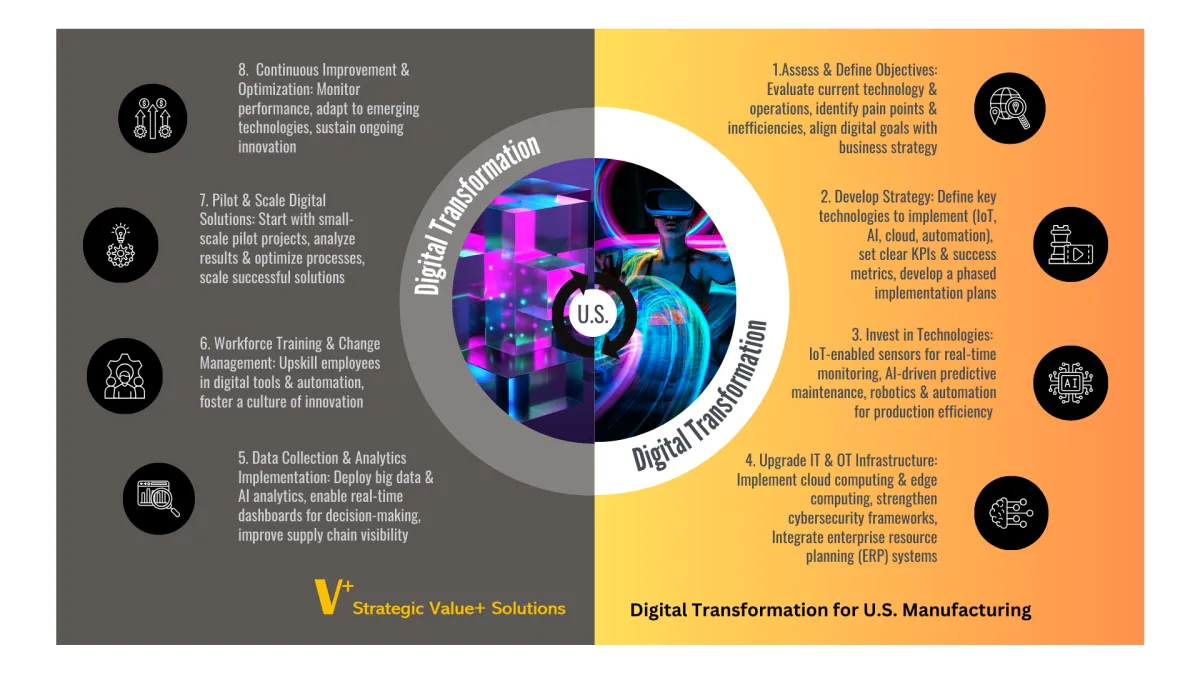

Leverage Our Digital Transformation Services Tailored for Small- & Medium-Sized U.S. Manufacturers

Take a look at the Digital Transformation/Industry 4.0 Process Chart below for birds-eye view or click the Learn More button.

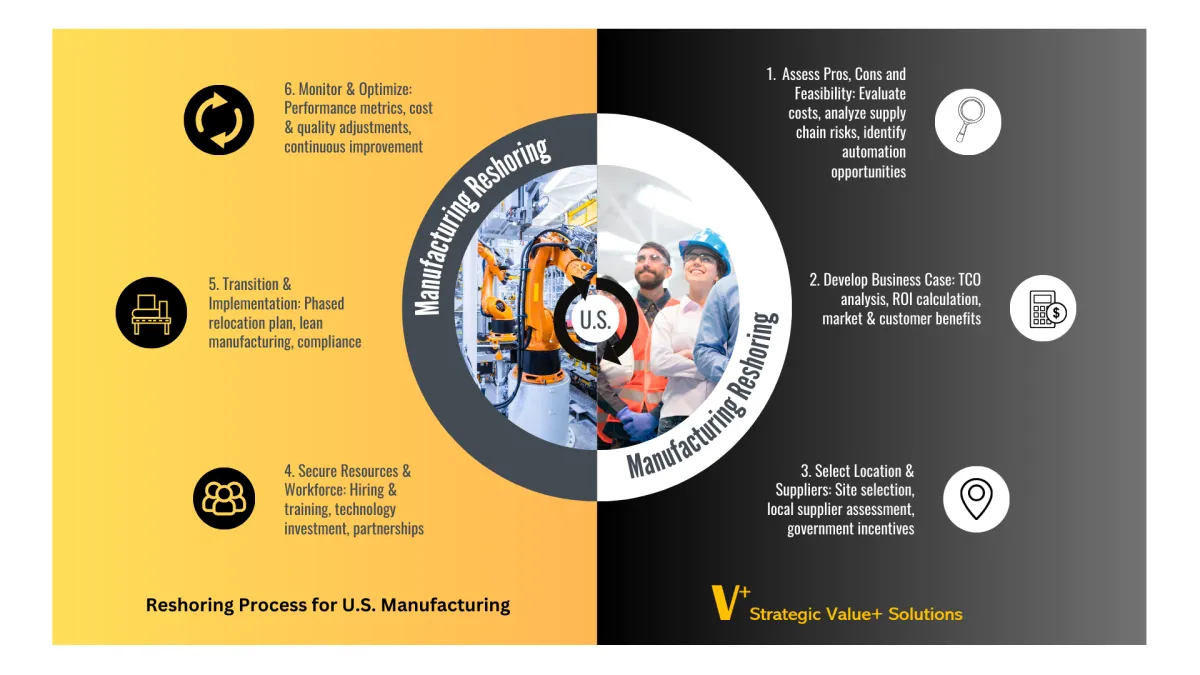

ATTENTION: U.S. Manufacturers

Leverage Our Reshoring Services Tailored for Small- & Medium-Sized U.S. Manufacturers

Take a look at the Reshoring Process Chart below for birds-eye view or click the Learn More button.

ATTENTION: U.S. Manufacturers

Leverage Our ISO & QMS Services Tailored for Small- & Medium-Sized U.S. Manufacturers

Take a look at the ISO & Quality Management Systems (QMS) Process Chart below for a birds-eye view and click the Learn More button.

FOR MANUFACTURING EXECUTIVES

Register for the Free U.S. Manufacturing Nexus Events

Our Speakers Are Leaders and Influencers in U.S. Manufacturing

Engage in timely conversations at the

"U.S. MANUFACTURING NEXUS:

AGILE COLLECTIVE INTELLIGENCE" Forums

WHAT IS THE U.S. MANUFACTURING NEXUS?

The NEXUS Is a Monthly Forum for Forward-Thinking Manufacturing Executives Ready to Tackle Today’s Challenges with Tomorrow’s Solutions: Revolutionizing Manufacturing Through Bold Ideas and Actionable Strategies.

Delve into hot manufacturing topics with fresh perspectives and new solutions.

JOIN US FOR THE DECEMBER 17TH, 2025 VIRTUAL EVENT:

"Disrupt or Get Disrupted . . . By AI"

Contributing to Our Deep Foundation of Knowledge and Experience

A Few of Our Benchmark Companies

Digitally Transforming Manufacturing:

Automotive & Transportation

Aerospace & Defense

Electronics & Electrical Equipment

Food & Beverage

Pharmaceuticals & Medical Devices

Chemicals & Petrochemicals

Consumer Goods & Packaged Products

Industrial Machinery & Equipment

Renewable Energy & Power Systems

Building Materials & Construction Products

Textiles & Apparel

Metalworking & Foundries

Plastics & Rubber Products

Oil & Gas Equipment

Agricultural & Farming Equipment

Furniture & Wood Products

Printing & Packaging

Mining & Materials Processing

Logistics & Material Handling Equipment

Other Specialized Industries (Jewelry, Firearms and Ammunition, Sporting Goods, Musical Instruments, etc.)

GIVING BACK

Organizations We Support

U.S. Economic and Workforce Development

Mental Health in the Workplace

STEM, Youth Engagement, Robotics

Contact Us

Strategic Value+ Solutions

(302) 215-4700

Connect with Us

Legal

© 2026 Strategic Value+ Solutions LLC.

All Rights Reserved.

Disclaimer

The information, insights, and recommendations provided by Strategic Value+ Solutions advisors are for general guidance and informational purposes only. While we strive to offer expert advice tailored to the unique needs of each client, our consulting services do not constitute legal, financial, or regulatory advice. Clients should seek appropriate professional counsel before making business decisions.

Scope of Services: Our firm provides strategic consulting across various aspects of manufacturing, including operations, supply chain management, financial optimization, workforce development, marketing, compliance, quality management systems, and business transformation. However, outcomes may vary based on external factors beyond our control, including political climate, economic conditions, regulatory changes, and market dynamics.

Limitation of Liability: While we make every effort to provide accurate and up-to-date recommendations, Strategic Value+ Solutions advisors are not liable for any direct, indirect, or consequential losses resulting from the implementation of our strategies, analyses, or advice. Clients assume full responsibility for any business decisions made based on our consultations.

Third-Party Relationships: Our firm may recommend third-party vendors, software, or professional services as part of our consulting engagements. These recommendations are made in good faith, but we do not guarantee the performance or reliability of any third-party providers. Clients should conduct their own due diligence before engaging with any external service providers.

By engaging with Strategic Value+ Solutions, clients acknowledge and accept the terms outlined in this disclaimer. If you have any questions or require further clarification, please contact us at [email protected].