Strategic Value+ Solutions

Enriching Lives Through Manufacturing

Smarter. Faster. Resilient. Built for the Next Era of Manufacturing.

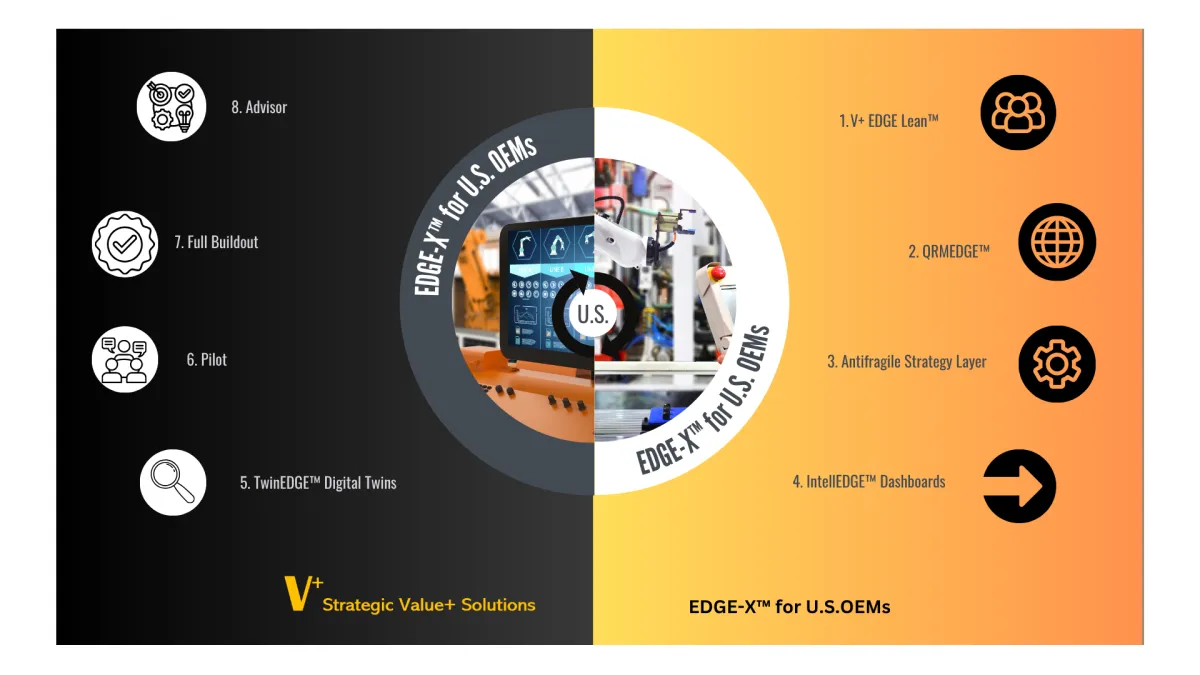

EDGE-X™

The Antifragile Transformation Framework for U.S. OEMs

EDGE-X™ is Strategic Value+ Solutions' flagship transformation framework that empowers U.S.-based Original Equipment Manufacturers (OEMs) to eliminate waste, reduce lead time, and gain strength through disruption.

Built by integrating the best of Lean, Quick Response Manufacturing (QRM), and Antifragile Strategy, EDGE-X™ equips your operation with the structure, tools, and resilience to win in an unpredictable world.

Whether you're reshoring, scaling, or adapting to complex customer demand, EDGE-X™ transforms your plant into a high-speed, future-ready factory.

Why Was EDGE-XTM Created?

The Pressures on OEMs Are Mounting:

The McKinsey Global Institute found that companies can expect a supply chain disruption of one month or longer every 3.7 years, potentially costing up to 45% of one year’s EBITDA over a decade (McKinsey, 2020).

The Reshoring Initiative reported that 287,000 U.S. manufacturing jobs were announced in 2023 due to reshoring and FDI—bringing the total since 2010 to nearly 1.9 million jobs (Reshoring Initiative, 2024).

Deloitte’s 2023 report noted that 72% of industrial executives consider reshoring and regionalization a strategic priority—but many are stalled by operational inflexibility, lead time issues, and supplier bottlenecks.

Traditional improvement methods like Lean Six Sigma have optimized stability and cost efficiency. But they often fall short in today’s high-mix, low-volume (HMLV) manufacturing environments. What’s needed now is a unified framework that also prioritizes speed, responsiveness, and resilience.

EDGE-X™ is an integrated modular,

enterprise-wide transformation framework

developed by Strategic Value+ Solutions.

The EDGE-XTM integrated system enables manufacturers to

reduce lead time, build flexible operations, and evolve continuously under uncertainty.

EDGE-X™ Includes

V+ EDGE LeanTM: Waste elimination, flow improvement, and operational discipline using proven Lean tools

QRMEDGETM: Time-based optimization across your entire system—from quoting to delivery—using QRM principles for lead time reduction and system responsiveness

Antifragile Strategy Layer: Resilience and adaptability built into your operation through redundancy, scenario modeling, and risk diversification for resilience, risk reduction, and adaptability under stress

IntellEDGETM Dashboards: Live tracking of manufacturing KPIs, MCT, supplier exposure, and operational fragility. Drive smart decisions with real-time executive dashboards monitoring key operational and fragility metrics.

TwinEDGETM: Simulate layouts, disruptions, supply shifts, and production strategies before you invest. Make data-driven decisions with scenario modeling and disruption simulations using digital twins.

Audit readiness, rework, conconformance

EDGE-XTM Is For

OEMs Who Are:

Reshoring or preparing to regionalize supply

Operating in high-mix, low-volume (HMLV) environments

Facing long lead times and supplier risk

Seeking real-time executive visibility across operations

Why Choose EDGE-XTM?

Transformation Made Practical for U.S. ORIGINAL EQUIPMENT Manufacturers

"A lack of structured, incremental pathways remains a key blocker, especially for SMEs and mid-tier OEMs." [World Economic Forum & McKinsey Report (2022) – “The Smart Industry Readiness Index”]

EDGE-X™ solves that.

EDGE-XTM

Flexible | Scalable | Built for U.S. OEMs

Cut lead times by 30–70%

Improve on-time delivery to 95%+

Shrink inventory by 20–50%

Speed up quoting and response cycles

Build resilience into sourcing, logistics, and production

Win reshoring business and government support with data-backed readiness

Most EDGE-X™ modules deliver measurable ROI within 4-6 months, on average, and varies depending on OEM readiness. Build a full transformation roadmap—modular, hands-on, and tailored to your goals.

Transformation Made Practical for U.S. OEMs

How to Get Started withEDGE-XTM

EDGE-X™

Flexible | Scalable | Built for U.S. OEMs

Book a Free Discovery Call:

We learn about your plant, your goals, and your current challenges.

Receive a Custom Transformation Roadmap:

Delivered in under 10 days. Includes ROI estimates, project phasing, and module fit.Start Where It Counts:

Asset? Ops? Workforce? You choose. We execute alongside you.

Most EDGE-X™ modules deliver measurable ROI within 4-6 months, on average, and varies depending on OEM readiness. Build a full transformation roadmap—modular, hands-on, and tailored to your goals.

Built to Scale with You

Why Now?

📊 The National Association of Manufacturers (NAM) reports that 74% of U.S. manufacturers plan to diversify or reshore their supply chains before 2026.

📊 The average OEM loses 8–12% of annual revenue due to quoting delays, missed delivery windows, and supply chain blind spots.

📊 OEMs that digitize operations, reduce MCT, and incorporate scenario planning stand to outperform their peers in responsiveness and profitability.

EDGE-X™ is built specifically for this moment in manufacturing history.

STILL NOT SURE?

Frequently Asked Questions

Do these questions help? We will also answer your questions at our discovery meeting.

What makes EDGE-X™ different from Lean or Six Sigma alone?

While Lean and Six Sigma are powerful for eliminating waste and improving consistency, they fall short in highly variable, custom, or disrupted environments. EDGE-X™ combines Lean with Quick Response Manufacturing (QRM) to reduce time-based inefficiencies and adds an Antifragile Strategy layer to build systems that adapt and improve under stress. It's the only integrated framework designed for speed, flexibility, and resilience in reshoring and supply chain-sensitive operations.

Is EDGE-X™ only for large manufacturers or can smaller OEMs benefit?

EDGE-X™ is designed for OEMs with 50 to 500 employees, especially those operating in high-mix, low-volume environments or navigating reshoring, supplier risk, or quoting delays. The program is modular—so smaller manufacturers can start with a focused pilot, while larger firms can adopt the full framework across sites.

How does EDGE-X™ help with reshoring or regionalizing production?

EDGE-X™ equips manufacturers to reduce lead times, right-size inventory, and simulate disruption scenarios before reshoring. The Antifragile Strategy layer helps de-risk supply chains and plan for dual sourcing or capacity redundancy. Plus, tools like TwinEDGE™ digital twins and IntellEDGE™ dashboards offer real-time visibility and layout modeling to ensure smoother, more cost-effective transitions back to the U.S.

How quickly can we see measurable results from EDGE-X™?

Most OEMs that implement the EDGE-X™ Pilot see measurable improvements in lead time, quoting speed, and on-time delivery within 90–120 days. Full operational transformations typically show dramatic cost, responsiveness, and resilience gains within 6–12 months. Key metrics tracked include MCT, fragility index, on-time delivery, and inventory turnover.

Can EDGE-X™ be integrated with our existing ERP, MES, or KPI systems?

Yes. IntellEDGE™ dashboards are designed to connect with most ERP and MES systems to track relevant Lean, QRM, and Antifragile KPIs. Our team will work with your technical staff to ensure seamless integration, customized reporting, and visibility across departments.

What is Manufacturing Critical-path Time (MCT) and why does it matter?

Manufacturing Critical-path Time (MCT) is the total calendar time from when a customer order is created until the first piece is delivered—measuring both value-added and non-value-added time. Unlike cycle time, MCT reveals hidden bottlenecks like quoting delays, batching, approvals, and waiting. Reducing MCT through QRMEDGE™ improves cash flow, responsiveness, and competitive positioning—especially for custom or high-mix production environments.

How does the Antifragile Strategy differ from traditional risk management?

Traditional risk management tries to minimize or avoid shocks. The Antifragile Strategy goes further: it helps your operation adapt, respond, and grow stronger when disruptions occur. This includes building redundancy, using stress testing, and designing supplier diversity or modular production systems. It shifts your mindset from recovery to strategic advantage through volatility, preparing your OEM not just to survive—but to thrive.

What kind of support does Strategic Value+ provide during and after EDGE-X™ implementation?

Each EDGE-X™ engagement includes expert facilitation, hands-on diagnostics, and tailored implementation support. Our team provides:

- QRM Cell design and coaching

- Lean value stream mapping and training

- Fragility indexing and Antifragile planning

- Dashboard setup and simulation modeling (via IntellEDGE™ & TwinEDGE™)

- For ongoing support, our EDGE-X™ Advisor program offers embedded fractional leadership, KPI reviews, quarterly strategy sessions, and guidance through future transitions or expansions.

What is QRMEDGE™?

QRMEDGE™ is a modular solution developed by Strategic Value+ Solutions that applies the principles of Quick Response Manufacturing (QRM) to reduce lead times across your entire enterprise—shop floor and office alike. It’s specifically designed for high-mix, low-volume (HMLV) manufacturers, where traditional Lean tools alone may not fully address time-based bottlenecks.

Built on the research of Dr. Rajan Suri at the University of Wisconsin-Madison, QRMEDGE™ focuses on reducing Manufacturing Critical-path Time (MCT)—the total calendar time from order to delivery. This includes wait times in quoting, approvals, purchasing, and batch scheduling, not just processing time.

By creating QRM Cells (cross-functional, self-managing teams) and redesigning workflows to minimize delays and handoffs, QRMEDGE™ helps OEMs:

- Cut lead times by 30–70%

- Accelerate quote-to-cash cycles

- Improve on-time delivery to 95%+

- Reduce overhead and excess inventory

- Respond more flexibly to reshoring or customer demand volatility

What is the EDGE-X™ Antifragile Strategy Layer?

The Antifragile Strategy Layer is a core component of the EDGE-X™ framework that equips manufacturers to not only survive disruption—but to benefit from it.

Inspired by the concept introduced by risk analyst and author Nassim Nicholas Taleb, “antifragile” systems are those that gain strength, capability, and adaptability under stress. Unlike fragile systems that break and robust systems that merely resist change, antifragile operations improve through volatility.

In the manufacturing context, the Antifragile Strategy Layer includes:

- Supply Chain Diversification – shifting from single-source to dual/multi-source suppliers, nearshoring, and regionalization.

- Redundancy Planning – creating modular capacity and safety margins in critical operations.

- Scenario Modeling & Stress Testing – using tools like TwinEDGE™ digital twins to simulate disruptions and test organizational responses.

- Fragility Indexing – quantifying exposure across suppliers, workflows, and workforce dependencies.

- TCO-Based Sourcing Decisions – prioritizing long-term total cost of ownership (TCO) over short-term landed costs.

By embedding these principles into daily operations and long-term planning, the Antifragile Strategy Layer helps OEMs:

- Recover faster from shocks

- Make smarter reshoring and sourcing decisions

- Reduce risk concentration and operational bottlenecks

- Build a culture of learning and adaptability

- OEMs that adopt this layer report measurable improvements in delivery reliability, margin stability, and strategic decision-making—especially in post-pandemic, reshoring-intensive environments.

It’s not about predicting the next disruption—it’s about being ready for any of them.

Contact Us

Strategic Value+ Solutions

(302) 215-4700

Connect with Us

Legal

© 2025 Strategic Value+ Solutions LLC.

All Rights Reserved.

Disclaimer

The information, insights, and recommendations provided by Strategic Value+ Solutions advisors are for general guidance and informational purposes only. While we strive to offer expert advice tailored to the unique needs of each client, our consulting services do not constitute legal, financial, or regulatory advice. Clients should seek appropriate professional counsel before making business decisions.

Scope of Services: Our firm provides strategic consulting across various aspects of manufacturing, including operations, supply chain management, financial optimization, workforce development, marketing, compliance, quality management systems, and business transformation. However, outcomes may vary based on external factors beyond our control, including political climate, economic conditions, regulatory changes, and market dynamics.

Limitation of Liability: While we make every effort to provide accurate and up-to-date recommendations, Strategic Value+ Solutions advisors are not liable for any direct, indirect, or consequential losses resulting from the implementation of our strategies, analyses, or advice. Clients assume full responsibility for any business decisions made based on our consultations.

Third-Party Relationships: Our firm may recommend third-party vendors, software, or professional services as part of our consulting engagements. These recommendations are made in good faith, but we do not guarantee the performance or reliability of any third-party providers. Clients should conduct their own due diligence before engaging with any external service providers.

By engaging with Strategic Value+ Solutions, clients acknowledge and accept the terms outlined in this disclaimer. If you have any questions or require further clarification, please contact us at [email protected].